O-Scale Coupler Conversion Info

To get the most out of your O-Scale railroad layout, you've got to have properly functioning couplers.

O-Scale is a custom coupler conversion scale.

We don't have specific coupler recommendations for specific locomotives or freight cars like we have on HO-scale or Large scale.With that said O-Scale coupler conversions are not that difficult if you follow some simple guidelines.

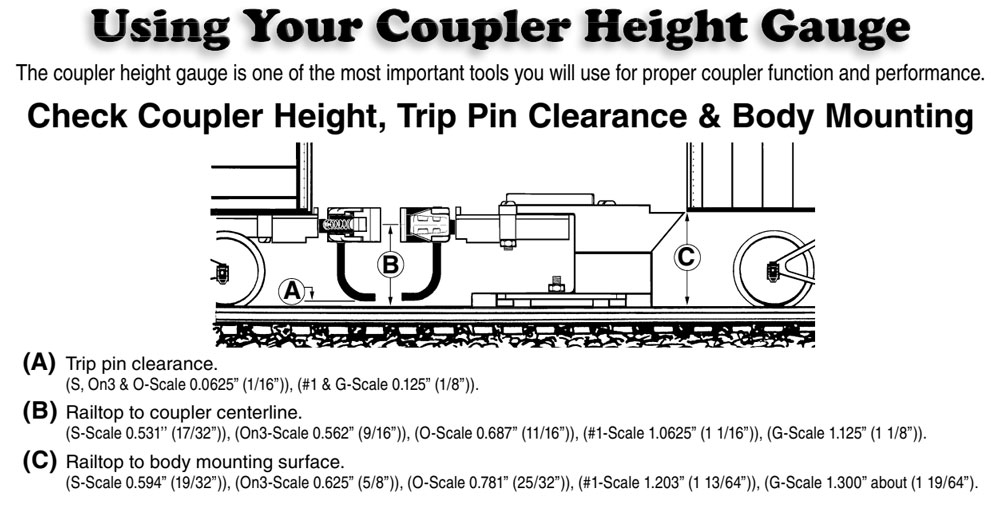

Use the #812 O-scale coupler height gauge. The #812 coupler height gauge is the most important tool you have for coupler conversions.

Most newer O-Scale products have a platform on the end of the car for coupler mounting. This makes coupler conversions much more convenient. If your car doesn't have a smooth, flat platform, you will have to build one. Don't worry, it sounds more intimidating than it is. You just need to cut and attach styrene shim stock to the bottom of the car to give yourself a smooth, flat coupler mounting surface.

We recommend mounting the coupler gearbox with screws so the coupler and gearbox are serviceable. We don't recommend glueing any gearbox to the car. If something needs to be adjusted, you would have to cut the gearbox off the car and that is just no fun.

It is important to remember that if you have to drill and tap holes, make sure you mount the coupler squarely on the centerline of the car and measure twice before drilling and taping your mounting holes. Remember, if the coupler is not mounted on the centerline of the car, the coupler trip pins will not align with the uncouplers properly and the coupler will not function the way it is intended to function.

So how do you determine the correct coupler height, you ask?

By using the #812 O-scale coupler height gauge of course.

Make sure you are using the height gauge and car on a straight piece of track.

If the #812 O-scale coupler height gauge wedge just slides under your coupler platform, the platform is the correct height for any of the O-scale centerset couplers (standard gearbox couplers #740, 745, 801, 804,805 or 816) or (short gearbox couplers #743 or 806) to be mounted to the platform with a screw. The bigger decision is what material you want the gearbox, and coupler made from, and the coupler style you want to use, and that is a personal preference.

If the #812 O-scale coupler height gauge wedge has a gap between the wedge and the coupler platform you would need to add shims between the car and gearbox to adjust the platform height to make the platform match the coupler height gauge wedge. Now, if the gap between the wedge and the coupler platform was off the thickness of the O-scale coupler shank, you could use an #742 overset coupler to correct the gap without having to shim down the gearbox for a centerset coupler for a cleaner look.

If the #812 O-scale coupler height gauge wedge hits the end of the car, not sliding under the car, then you can do a couple of things. You could put shims between the trucks and underframe to raise the car body or use the #747 underset coupler. The #747 will only resolve the low mounting height if the coupler height gauge wedge to the mounting platform is only off the thickness of the coupler shank or less. Additional shimming may still be required. If the mounting height is off more than the #747 coupler can compensate for, you will have to place shims between the trucks and the car body to raise the car and coupler to the correct height.

Once you have your couplers mounted on the car, you need to spin the coupler height gauge around and make sure the centerline of the coupler on the car and the coupler on the height gauge match. If they are off fine, tune the height as necessary. If you glued the gearbox on your car you will have to cut it off and start over.

Now your car is ready for operation on your layout.