Custom Waterslide Decal Printing

Looking to add you own custom touch? Want to create your dream model? Look no further than our custom decal printing service featuring high-quality results and personal service.

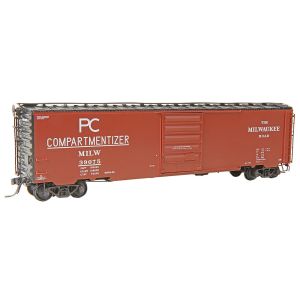

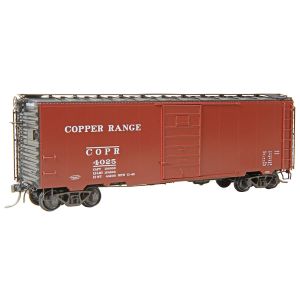

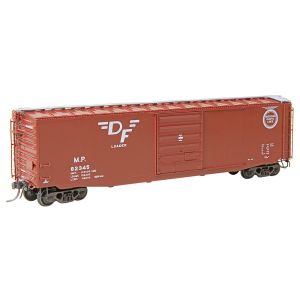

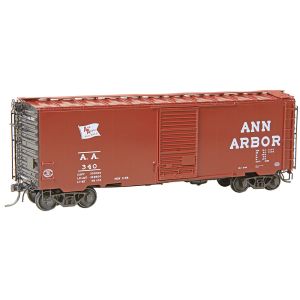

We've been printing high-quality custom waterslide decals since 2005. We specialize in ALPS Thermal and Full-Color Laser decals with a quick 2-3 business day turnaround. Our custom decals are perfect for model trains, guitar headstocks, model cars, model planes, fly rods, restorations, bicycles, fingernails, company logos, and more.

We do not reproduce copyrighted or trademark material without written permission. No exceptions!

Just because a logo is old doesn't mean the owner relinquishes their trademark.

All logos, names, and artwork from movies, TV, games, toys, sports teams, automobile logos, and brand logos are copyrighted or trademark material examples.

We require written permission from the copyrighted or trademark material owner. Suspect material is also required to show permission for reproduction.

ALPS

CUSTOM

DECALS

LASER

CUSTOM

DECALS

WHAT'S THE DIFFERENCE?

| ALPS Printing | vs | Laser Printing |

|---|---|---|

| Black, White, Cyan, Magenta, Yellow, Red, Blue, Green, Metallic Silver, Metallic Gold | Printable Colors | Full Color |

| 3† | Maximum Colors* | Unlimited |

| Yes | Print White Ink | No |

| Yes | Print Metallic Ink | No |

| 600 dpi | Resolution | 600 dpi |

| 8" x 10" | Decal Image Area | 8" x 10" |

| 1 | Minimum | 1 |

| *Colors are 33% translucent.

†Red, blue, or Green count as 2 of the 3 maximum colors. |

||

Creating Custom Waterslide Decals

So you’ve decided to break from the mundane and create your own custom artwork for your project – Great! But, just how do you decide which printing technique to use? Don’t worry, we’ll break it all down one by one and show you the pros and cons of every option.

There are several different methods to get your custom artwork from digital to decal. Printing methods like ALPS Thermal, Laser, Offset, and Silk Screening is commonly used for such a task. But which one should you choose? Let’s take a look at the technology, benefits, and shortcomings of each type.

ALPS Thermal Printing

The ALPS Thermal printer uses a wax/resin “ink” that is transferred onto the decal paper. The colors are waterproof and make a beautiful decal.

Another unique benefit of ALPS Thermal printers is their ability to print with white and metallic colors. Since most printers can’t print these colors, this gives you some nice options that you otherwise wouldn’t have access to.

White?! That’s right, white is a printable color with the ALPS. This is invaluable for most decal artists since you can print additional colors right over the white ink. Colors laid over white are more vivid and allow the decal to look great when applied to anything; regardless of the object’s color.

Besides these benefits, ALPS printers can quickly and cheaply print a single sheet thus avoiding expensive setup costs associated with some other methods of printing.

So what’s the catch? Well, there’s a pretty big one: You can only make about 10 actual colors with the ALPS Thermal printer. You’re basically limited to a selection of black, white, cyan, magenta, yellow, red, blue, green, metallic silver, and metallic gold. Not only that, but the ALPS can only reliably print with 3 colors at a time due to the thickness of decal paper. Any more than 3 layers of color can result in scratching of the inks as the paper passes through the printer multiple times. Care must be taken to protect the decal before it’s applied to prevent scratching, decals have to be coated with "Liquid Decal Film" to make them scratch resistant.

Oh, and if you do want to use red, blue, or green in your decal, you should know that the ALPS creates these three colors by “mixing” two other colors. So if you’re printing red (yellow + magenta) you’ve already used up 2 of the 3 available colors for your decal, leaving you with only one more color to choose from.

In spite of these limitations the ALPS printer is still the most popular option for waterslide decals since most decals aren’t overly colorful or have complex shading. Oftentimes, decals are simply black or black and white.

Full-Color Laser Printing

Full-Color Laser printed waterslide decals are exactly what they sound like: full color! With this method, you aren’t limited to 3 colors like with the ALPS. The resolution is just as crisp and the color choices are nearly limitless. And just like the ALPS, you can print single sheets quickly and cheaply.

Color laser printers use a standard CMYK 4-color process. CMYK stands for cyan, magenta, yellow, and black. With this technology, all four of the available inks are precisely mixed and blended allowing for high color counts and even gradients.

So what’s wrong with Full-Color Laser printing? Nothing, as long as you don’t want white or metallic colors. As we said before, most printers can’t print white ink. So you must carefully consider what your decal is going to be applied to.

Inks are semi-opaque, meaning that they have some transparency; about 33% transparency on average. So if you create a beautiful yellow and red decal and slap it onto a blue object you’ve now got a green-ish/blue-ish decal. The only reliable way to make sure your laser-printed decal looks correct is to apply it to a white object.

Another thing to keep in mind is that laser-printed decals will scratch, just not as easily as ALPS-printed decals. Care must be taken to protect the decal before it’s applied to prevent scratching. Even with these setbacks, nothing beats a full-color laser-printed detail for sheer color selection.

Offset Printing

Now we’re getting into the heavy hitters. Offset printing can create some of the highest-resolution graphics in all of the printing. We’re talking 3600 dpi which allows for legible fonts all the way down to 0.5 points. Not only that, but you can print any combination of colors that you want, including white! It’s truly the best of both worlds.

So why aren’t we all printing decals with the offset printing method? In a word: cost. Offset printing requires very specialized equipment like high-quality image setters, developer machines, and floor-standing printing presses. It also takes a lot of time to transform a digital graphic into an offset printed decal – and the more colors you have, the longer it takes. Typically graphics need to dry for 30 days between color switches. So if you’re printing a multi-color decal, be prepared to wait a while. The setup and operation of offset printing take a substantial amount of time and skill.

This leaves offset printing squarely in the realm of mass production. If you need thousands of copies of your decal and money is no object, you might consider this method. Even then, you’d need to find a company that’s willing to invest the time in printing that many decals for you.

Silk Screen Printing

This method is the traditional decal printing technique where a mesh is used to transfer ink onto a substrate, except for areas made impermeable to the ink by a blocking stencil. Only one color is printed at a time, but several screens can be used to create a multicolored image.

Much like offset printing, there is a significant amount of setup and labor involved. The more colors that are needed, the more stencils are required. Once again, any color combination can be used, including white, but the significant time and cost involved relegate this method to mass production as well.

In addition to these factors, silk screen printing cannot produce nearly the same resolution and quality as any of the other methods and is best suited for large decals that don’t require high fidelity.

A Word On Inkjet Printing

A tempting and often considered solution to at-home decal printing is the venerable inkjet printer. They’re inexpensive to use and easy to find. As appealing as inkjet printers may seem, they simply won’t work.

Sure, they’ll print the colors and resolution that you want (excluding white, of course), but there’s one glaring problem with printing decals with an inkjet printer: the ink is water-based! This means that as soon as you go to apply your inkjet-printed waterslide decal, the ink will start to dissolve.

Some workarounds have been developed to try and make inkjet decal printing viable. Specifically, some companies produce inkjet-compatible decal paper. This special paper requires that you first print the decals, then apply a second sheet of clear film over the top of the freshly printed sheet. Unfortunately, this results in a rather thick decal that will appear noticeably raised when applied to an object.

Decisions, Decisions

So what is the best solution for custom decal printing? The answer is: it depends. It depends on your specific artwork requirements and the color of the object you place the decal. If you have a white object, then the full-color laser is a great option. If you have a colored object and you need white, then ALPS is your best bet.

- ALPS Thermal Printing - Best for decals being applied to non-white objects. Can print white and metallic.

- Full-Color Laser Printing - Large color selection but must be used on white objects.

- Offset Printing - Full color including white, but prohibitively expensive. Hard to see white.

- Silk Screen Printing - Colorful and durable, but low resolution. Complex and expensive.

- Inkjet Printing - Not recommended due to ink being water-soluble.

So there you have it. Now that you know the pros and cons of each method, you can pick the right one for your project.