Roco HO Scale Coupler Conversions

| Whisker® Metal Coupler | Standard Coupler | Other Coupler Options | |

|

|

+

Kadee® NEM 363 to |

||

|

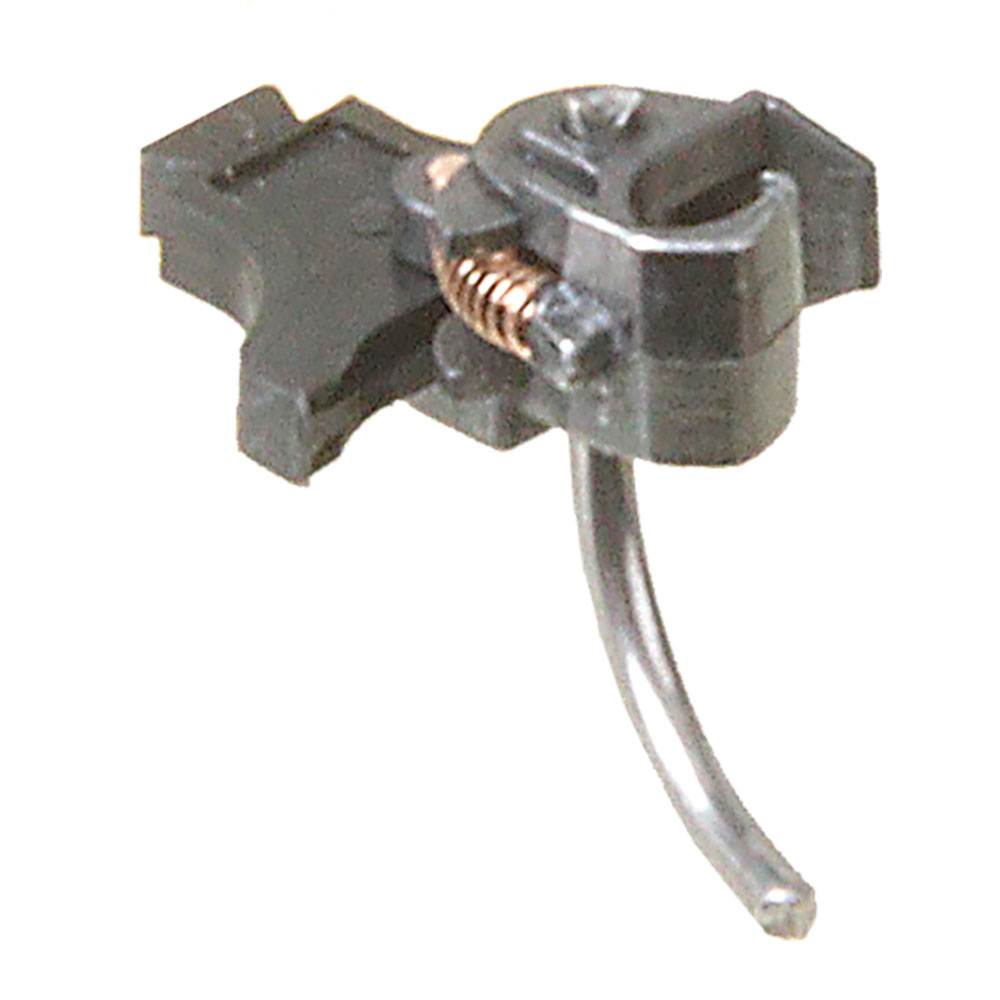

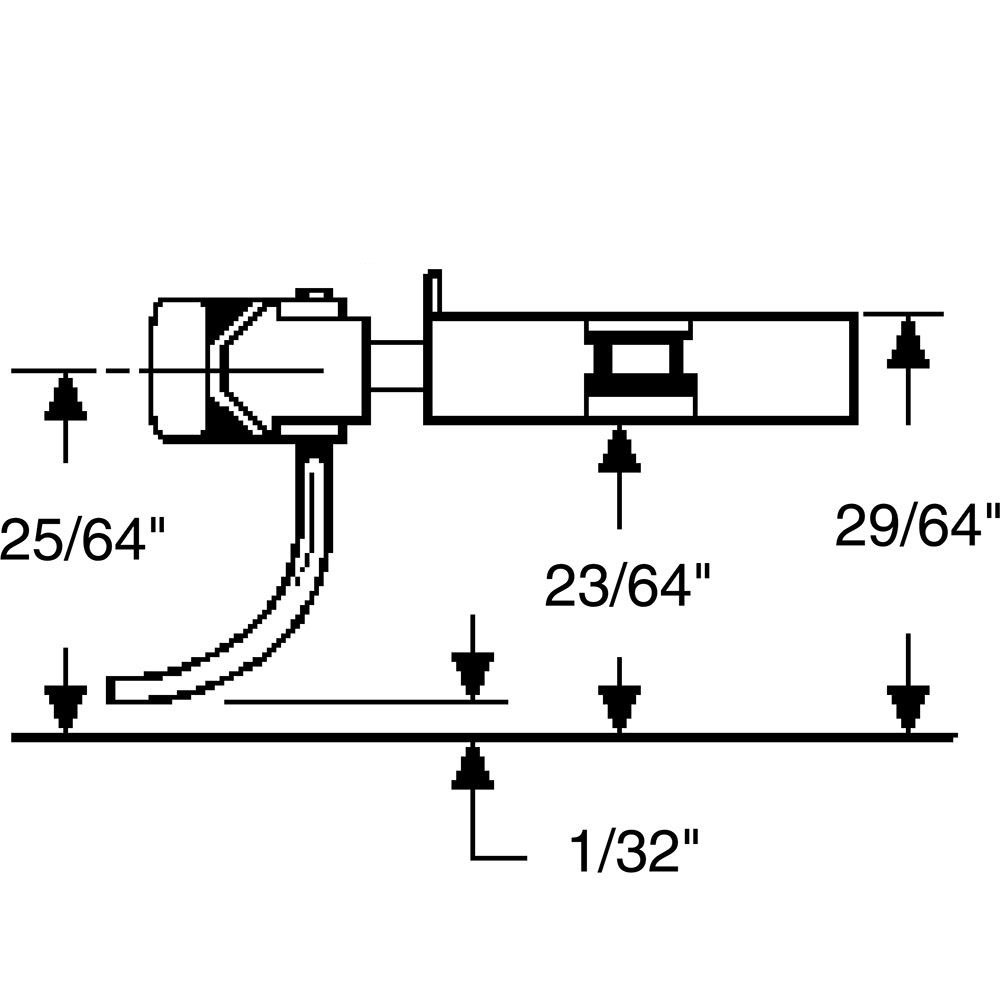

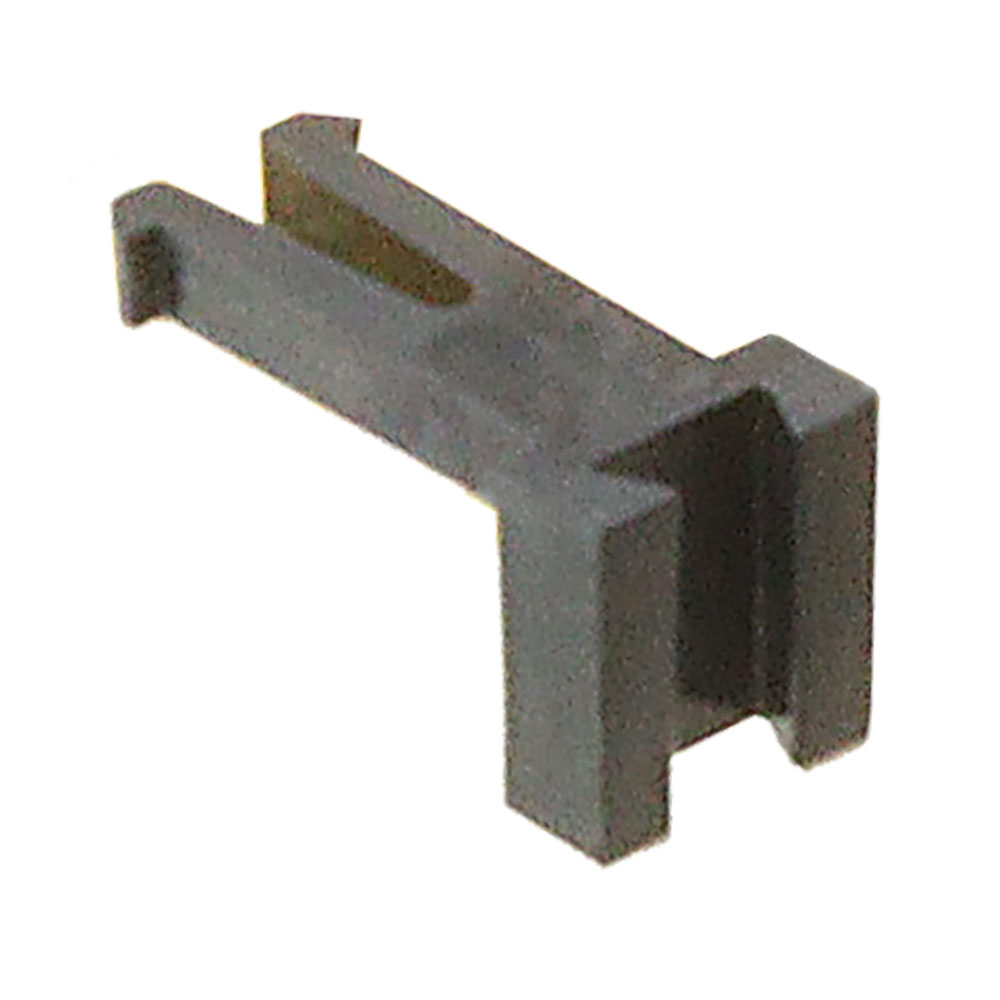

#141

in a #252 Gearbox |

|

||

|

|

+

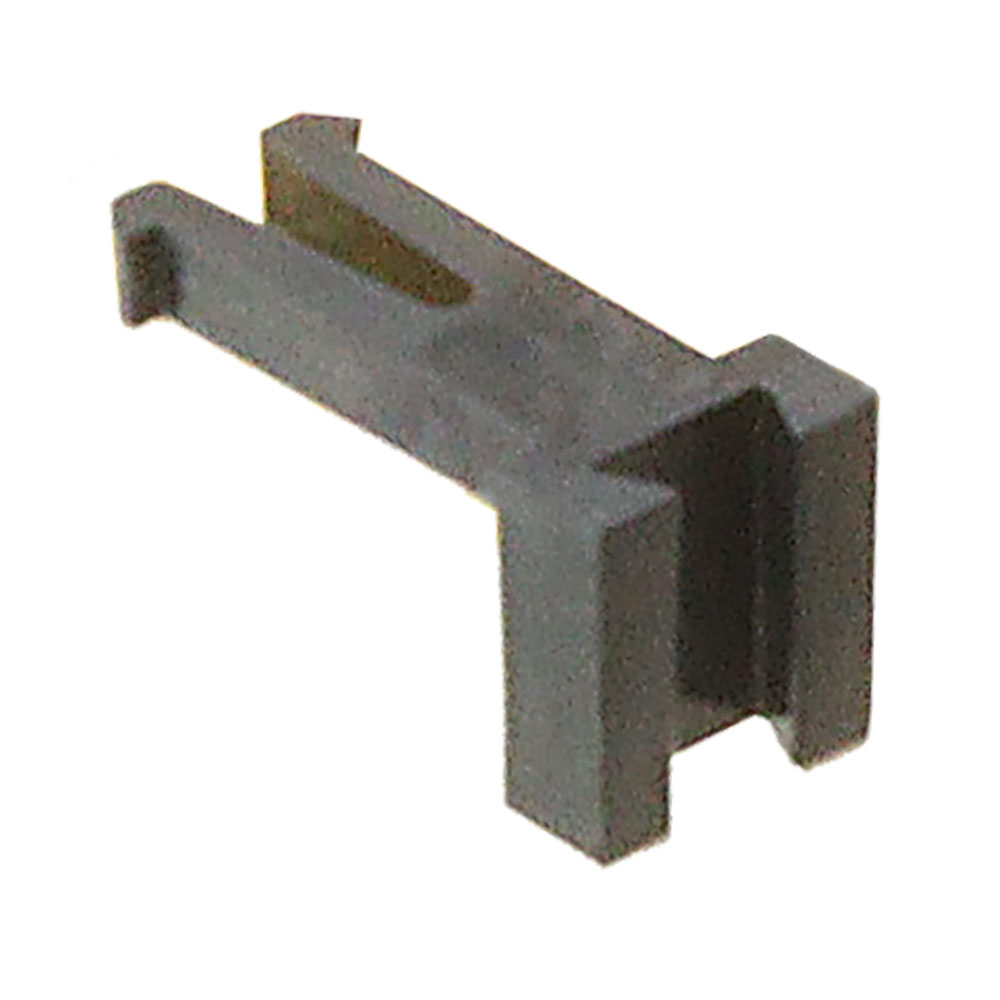

Kadee® NEM 363 to |

||

|

|

+

Kadee® NEM 363 to |

||

|

+

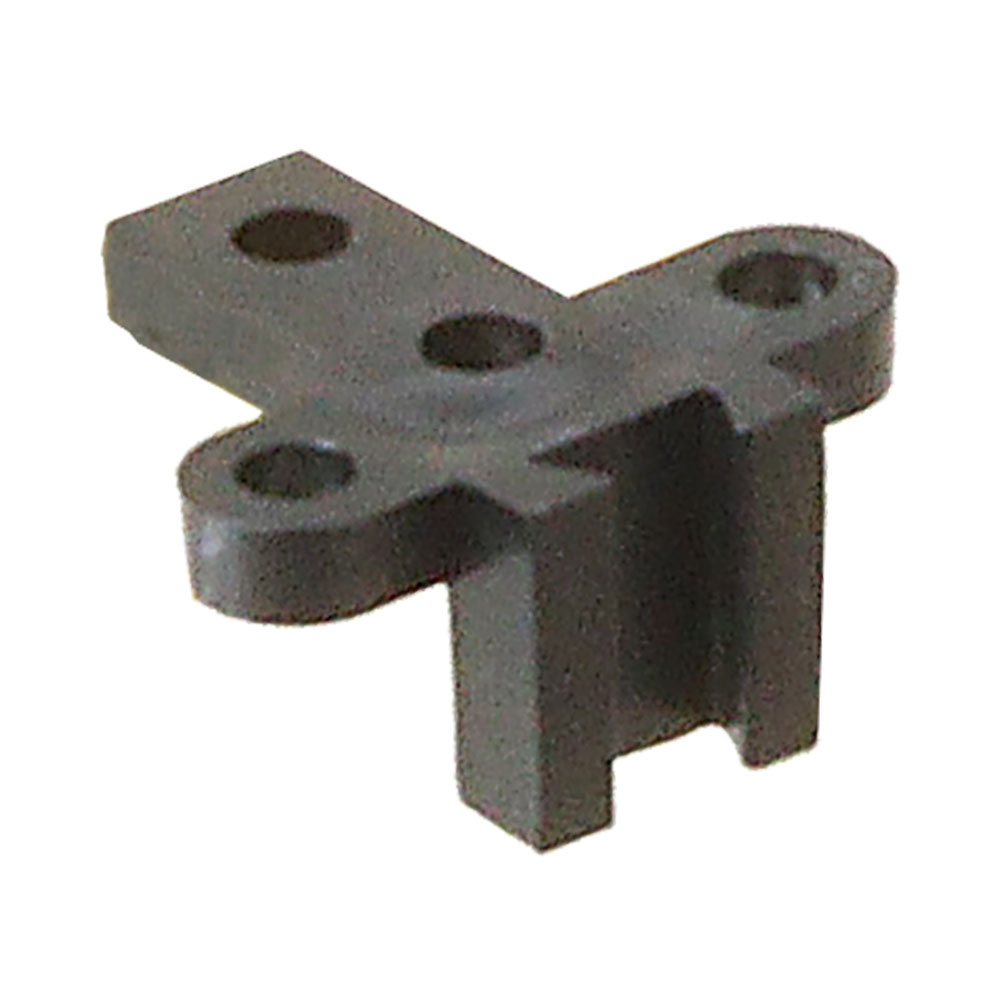

NEM Pocket |

+

Kadee® NEM 363 to +

NEM Pocket |

||

|

+

Kadee® Bolt-on |